AUTOS

Good Tesla, bad Tesla: Model 3 thrills while quality lags

The Detroit News

In early 2018, Sandy Munro and his colleagues at Munro & Assoc. tore down a Tesla Model 3 over three months and assessed its components and build quality. Results: 1) build quality the worst they have seen, 2) electronics systems tops in class. Manufacturers like Toyota have since bought his report.

Henry Payne, The Detroit News

Munro & Assoc. of Auburn Hills dis-assembled a Tesla Model 3 and found its electronic systems (foreground) to be the most-advanced in the auto industry.

Henry Payne, The Detroit News

In this Dec. 18, 2018, photo Tesla vehicles sit in a parking lot in Chicago. Tesla paint issues held up many Tesla orders as a supplier was brought in from August-December to touch up paint issues.

Teresa Crawford / AP

Munro & Assoc. CEP Sandy Munro points out the three different fastening systems for the Tesla Model 3 rear door fame - an example of the manufacturing complexity required of the Tesla.

Henry Payne, The Detroit News

From Left: The Tesla Model 3 80.5 kWh battery (1 of 4 similar slabs), and units from the BMW i3 (22 kWh), and Chevy Bolt (60 kWh). Munro says the Tesla is the most advanced of the three in its packaging.

Henry Payne, The Detroit News

At Munro & Assoc. of Auburn Hills, the shell of a Tesla Model 3 sits in front of tables full of its innards - electronics, batteries, electric motors, cables, suspension, more.

Henry Payne, The Detroit News

The full under-carriage battery storage container for the Tesla Model 3. Two of the 4 packs have been removed by Munro & Associates.

Henry Payne, The Detroit News

Tesla Model 3 electronic system components that control the drive-train and battery. Together they fit in a module under the rear seat - the most advanced electronics that Munro & Assoc. have seen in an electric car.

Henry Payne, The Detroit News

"TOO MANY PARTS" tells the tale of Munro's assessment of Tesla's heacy, overly-complex chassis design. The chassis contrasts with electrical systems that Munro found to be lightweight and efficient.

Henry Payne, The Detroit News

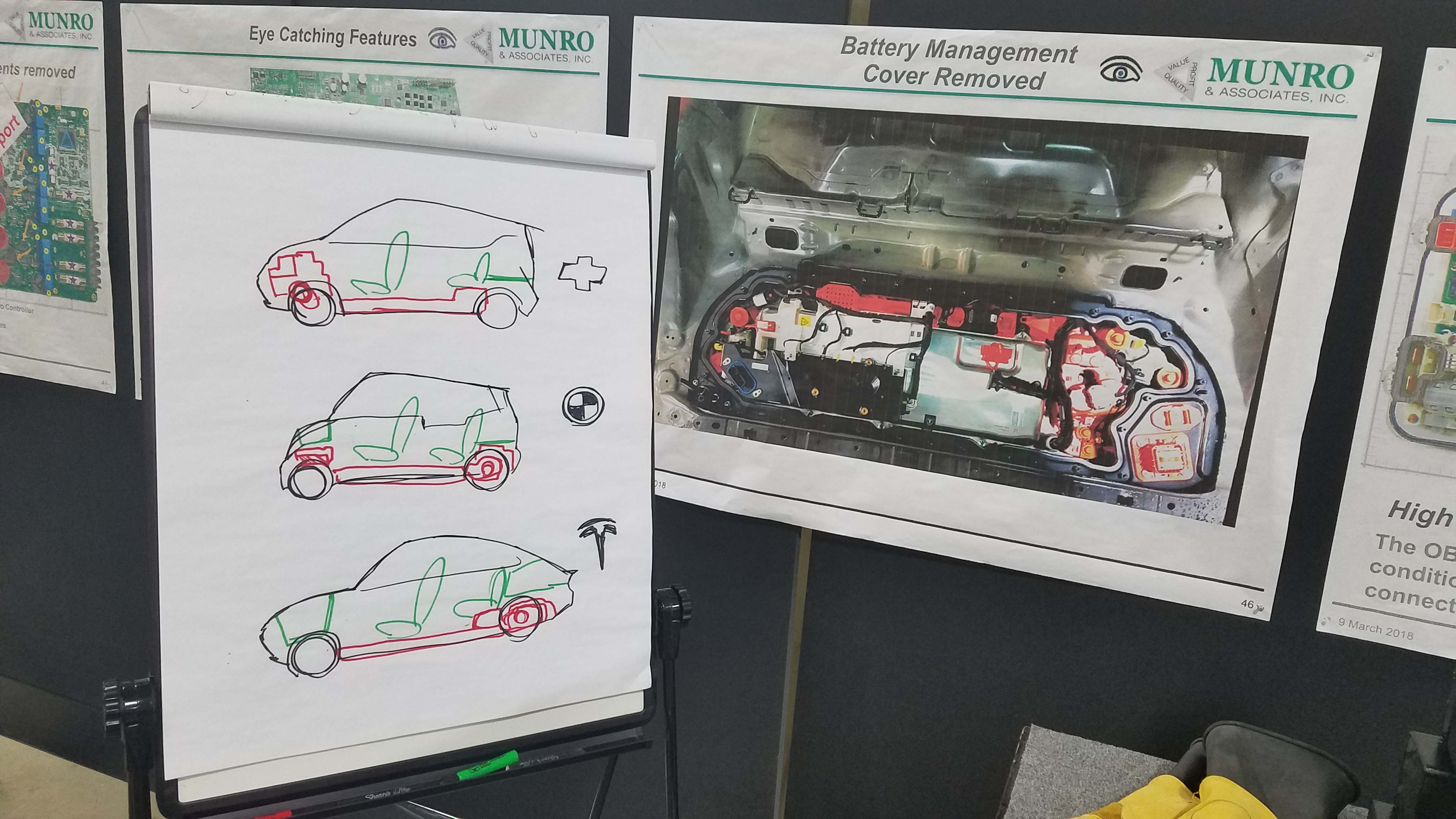

An illustration of the different, lithium-ion, electric drive-trains in the Chevy Bolt, BMW i3, and Tesla Model 3. In the background is a picture of where the Model 3 control systems fit in a module under the rear seat.

Henry Payne, The Detroit News

Munro & Associates dis-assembles multiple cars for evaluation. This is a BMW i3 chassis stripped down to its carbon-fiber backbone.

Henry Payne, The Detroit News

Munro & Associates offices in Auburn Hills, Michigan. The engineering firm tore down a Tesla Model 3 inside similar to the 310-mile-range, RWD Model 3 sitting out front.

Henry Payne, The Detroit News